Quite rightly, cash flow and material costs are always given priority when selecting between a Universal or Polymer specific Masterbatch. So, it is not uncommon to question which is the better option for your specific requirements.

We believe that there are advantages and disadvantages to either option, here we'll examine them both in an effort to provide you with enough information to help you to decide.

A universal masterbatch is created with a carrier system that is designed to work with various types of polymers, while a polymer-specific masterbatch is produced solely for use with one specific polymer grade.

Universal masterbatches offer a convenient and efficient colouring solution, as they are readily available off the shelf in quantities ranging from 1kg to 1000kg or more. They can also reduce costs as they are compatible with over 21 different types of polymers. This means that instead of ordering several polymer-specific masterbatches, you can use one universal masterbatch to colour a variety of different polymers.

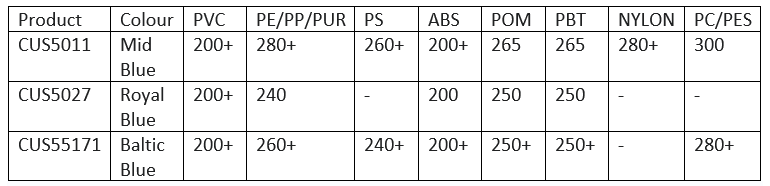

It's important to note that not all Universal Masterbatches are compatible with all polymers due to the specific pigments used in each masterbatch. To determine compatibility, please refer to the CUS colour chart for recommendations Here.

A polymer-specific masterbatch has been formulated using the same base polymer as the polymer in which it will be used. Depending on the specified polymer, it could be a more cost-effective option. However, this type of masterbatch is typically only suitable for use with the specific polymer for which it has been formulated.

The automotive sector, among other industries, often chooses polymer-specific masterbatches because of their capability to integrate functional additives, such as UV stabilizers, which reduce the harmful impact of UV radiation on the polymers employed. Furthermore, when the same base polymer is used in both the masterbatch and the target polymer, it can lead to better homogenization within the target polymer, enhancing its overall performance.

However, if the client decides to alter the polymer specified in the manufacturing process, the limited polymer compatibility of the original masterbatch could significantly compromise the quality and performance of the final product. This may necessitate the formulation of a new masterbatch to address the issue, resulting in additional costs. Additionally, the unused old masterbatch left in the warehouse could also contribute to the overall expenses.

When several types of polymers are needed to assemble a component, it is crucial to achieve a consistent and accurate colour match across the range of polymers to establish a unified brand identity and satisfy the end buyer's expectations.

Achieving a uniform colour across diverse polymers requires specialised expertise in colour development, knowledge of the distinct properties of each polymer, and an understanding of how these polymers will interact during the processing and assembly phases.

Colourhouse masterbatch technical knowledge and experience in working with various polymers can be crucial in achieving a consistent colour match across different polymers. Colourhouse can provide guidance on the selection of the appropriate masterbatch, colour matching techniques, and processing conditions to achieve the desired result.

It is important that we work together to develop a customized solution that meets the specific requirements of the application and achieves a consistent and accurate colour across the range of polymers used in the assembly of the component.

Here Colourhouse Masterbatch, we are constantly exploring ways to help our clients to reduce costs. While we have already outlined the benefits of our two existing masterbatch options, we would like to introduce a third option.

Our skilled technical team can create a masterbatch to your specified colour incorporating any necessary functional additives by utilizing our Universal Carrier system. The masterbatch will be custom-designed to match your specified polymer and ensure that the end product meets the desired performance requirements of the end component.

If your client decides to change the specified polymer used in the manufacturing process, our Universal Carrier system provides greater flexibility in using up redundant stock, rather than being left with a warehouse full of polymer-specific masterbatch that may never be used.

While we may still need to formulate a new masterbatch to achieve the same exact colour and physical properties of the original masterbatch when used with the alternative polymer, the option of using up redundant stock significantly increases, resulting in potential cost savings.

It is important to note that the compatibility of the masterbatch product with the alternative polymer must be verified by consulting with Colourhouse Masterbatch before usage.