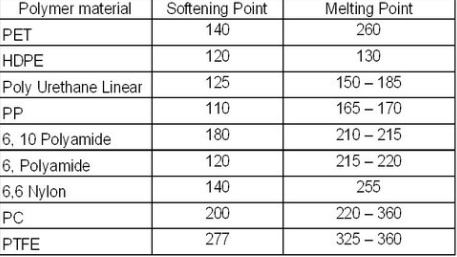

Selecting the right pigments is crucial when formulating a masterbatch. While the process is more involved than we can cover in a brief overview, we'll touch on the key principles our technical team follows. First, we determine the polymer's melting point based on information from the customer. This step is fundamental to the pigment selection process.

The polymer's melting point heavily influences the pigment options available for the masterbatch. For example, a pigment with a heat stability of 130 degrees may be suitable for HDPE but not for a polycarbonate masterbatch, which requires a pigment with a higher heat stability of 220 degrees. Therefore, it's essential to consider the correct pigment options for the specific polymer being used to ensure the masterbatch's quality and performance.

We can collaborate with you based on the information provided to ensure that your manufactured product is both legally compliant and suitable for the markets you intend to target.

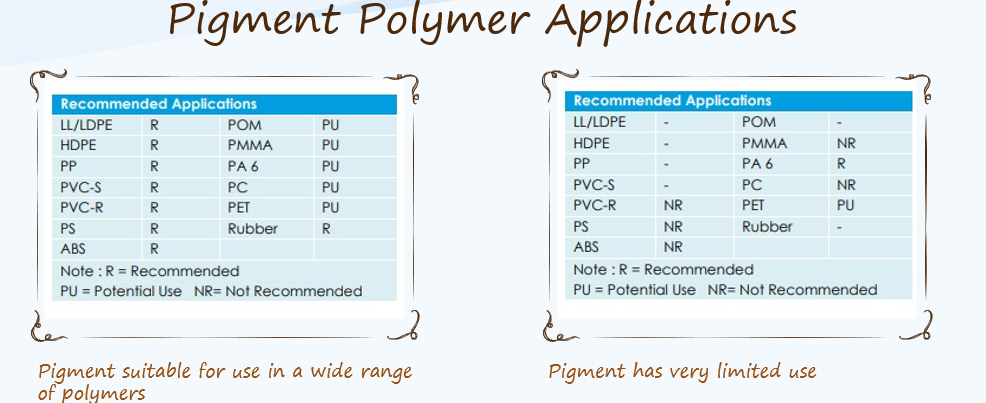

Below is a summary of Technical data we received for pigment red 253 from two different suppliers, As seen in the image provided, the pigment on the left offers more options for polymer compatibility than the one on the right.

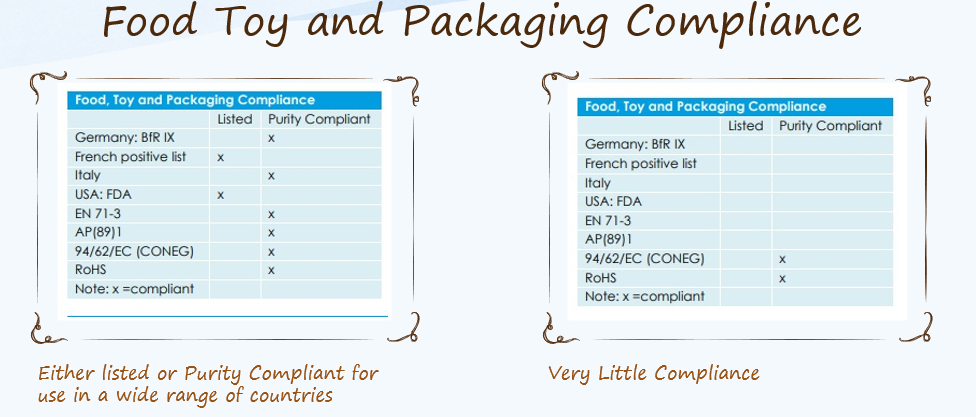

When developing a Masterbatch product, it is essential to consider the end-use and any regulations that must be followed to ensure that the product is safe for consumers. If the product is a food toy or packaging, there may be specific regulations that must be followed to ensure that the product does not pose a health risk to consumers.

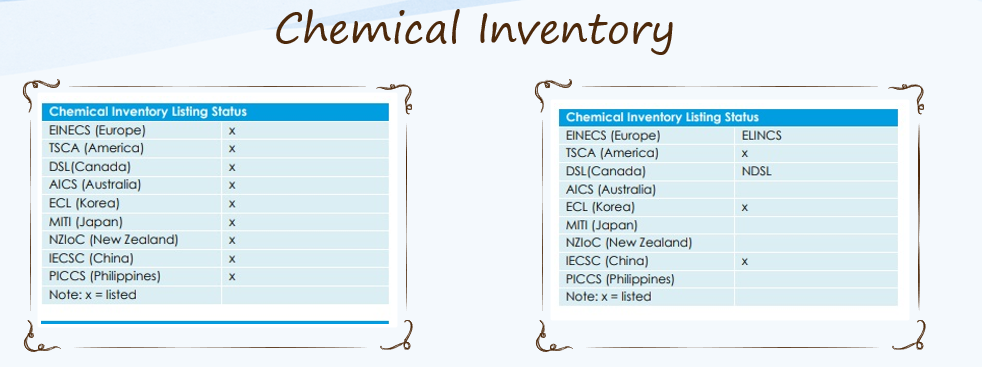

Furthermore, if the product is sold worldwide, it is essential to consider the regulations of each country where the product will be sold. Different countries may have different regulations regarding the materials used in the product, so it is important to ensure that the product complies with all relevant regulations.

One way to ensure compliance with various regulations is to use a masterbatch that has already been certified to comply with relevant regulations. This can save time and money compared to developing a new masterbatch that meets the requirements of each individual country.

Ultimately, by considering the end-use and relevant regulations, manufacturers can ensure that their products are safe for consumers and comply with all necessary regulations.

Failing to comply with these regulations may result in expensive legal problems and could potentially damage the brand's reputation.

While the pigment on the left may seem superior in all aspects, it is possible to achieve the same end colour with either pigment. Therefore, it's crucial to be cautious when someone claims to offer a "colour match" or a cheaper (or more expensive) alternative for a specific product, RAL or Pantone colour.

From this example, hopefully you can see that not all colours are formulated equally, Providing as much information as possible to your masterbatch supplier is highly recommended to ensure you get the desired outcome.