Masterbatch is a widely used product in the plastic industry. It is used to add colour, special effects and to improve the physical properties, However, the effectiveness of the masterbatch can be impacted by the various processing conditions of the application.

The type of machinery being used can significantly impact the quality of the final product when processing polymer with a masterbatch. The ability of the masterbatch to mix evenly with the polymer is highly dependent on the machine being used and the duration of the process. Certain machines have better mixing capabilities than others, and a machine that is good at mixing will ensure that the masterbatch is evenly distributed throughout, resulting in a high-quality final product. On the other hand, a machine with poor mixing capabilities may cause the masterbatch to not mix in properly, resulting in an uneven final product that does not meet the desired specifications.

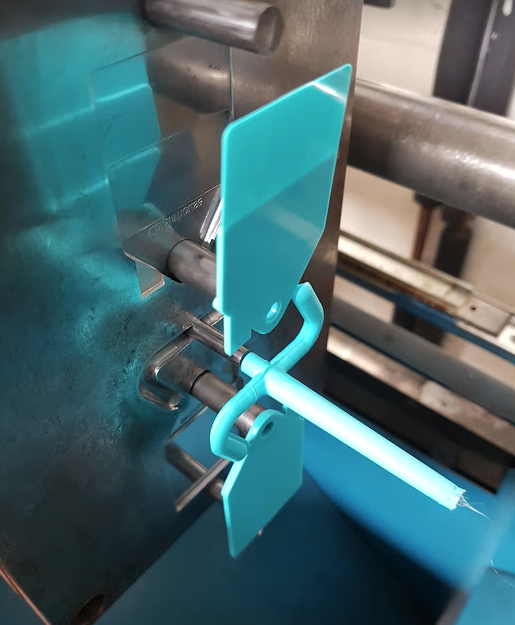

To address this issue, it may be beneficial to use a masterbatch formulated with a higher addition rate. This will allow for a larger amount of masterbatch to be dosed into the polymer, which can help ensure that the desired colour or properties are achieved even with a less capable machine. However, When using masterbatch in an injection moulding machine, it is important to optimize process parameters such as the screw speed, injection speed, and melt temperature. These parameters can significantly affect the mixing efficiency and final product quality.

For example, increasing the screw speed can improve the shear rate and promote better mixing of the masterbatch. Similarly, optimizing the injection speed and melt temperature can ensure that the masterbatch is uniformly distributed throughout the molten polymer, resulting in a high-quality final product.

By fine-tuning these process parameters, it is possible to achieve better integration of the masterbatch and improve the efficiency of the injection moulding process."

The type of polymer being used may also affect the efficiency of the masterbatch. Certain polymers may be more or less receptive to the masterbatch, which can impact the colour or functional properties of the final product. For instance, polyethylene and polypropylene are widely used polymers, but each has unique properties that affect how they respond to masterbatch. Polyethylene has low surface energy and is more difficult to colour than polypropylene. Therefore, it may require a different type of masterbatch to achieve the same colour intensity as polypropylene.

To ensure that the masterbatch integrates effectively into the plastic and provides the desired properties and appearance, it is crucial to consider all of these factors and choose a masterbatch that is suitable for your specific application. By selecting the right masterbatch, you can ensure that it integrates effectively into the plastic, resulting in a final product with the desired properties and appearance.

Selecting the right masterbatch for your application is critical. Factors such as temperature, capability, duration of the process, and the type of polymer being used should be considered when selecting the appropriate masterbatch. By doing so, you can ensure that the masterbatch integrates effectively into the plastic, resulting in a final product with the desired properties and appearance, while also improving efficiency and reducing costs.