When it comes to reducing costs and getting value for your money, Colourhouse Masterbatch Ltd understands the importance of cost reduction, particularly in the current economic climate. However, we believe it is important to dispel the common misconception that the lower the addition rate of a masterbatch, the greater the cost savings in your next project.

While some may use this concept as a selling point, we at Colourhouse prefer to take the time to understand your project and work with you to consider the bigger picture. We believe in offering tailored solutions that can help you achieve optimal results while keeping costs under control.

To explain the term "addition rate" or "let down ratio" in simple terms, it refers to the proportion or percentage of masterbatch that needs to be blended with the specific polymer to attain the desired colour and opacity, along with the appropriate level of functional additives, in the final moulded product.

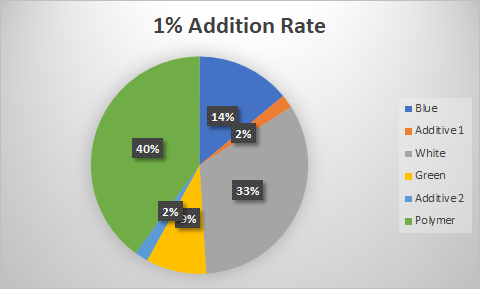

If we look at the basic pie chart of a 1 % masterbatch we can see the ratio of the individual components within the formulation.

To create a masterbatch formulation that provides the necessary level of UV protection for the final component, it is crucial to ensure that the correct amount of UV stabilizer additive is present in the moulded part. If the component doesn't contain enough protection, it may fail and not perform as intended.

To ensure that the final component has the required level of functional additive, increasing the addition rate of a masterbatch is often necessary. However, this may affect the desired colour of the component. To maintain the correct colour and opacity, the amount of pigment within the masterbatch may need to be adjusted, typically reduced. This reduction in pigment content allows for more additive to be included in the formulation, ensuring that the final component has the necessary level of protection while still achieving the desired colour and appearance.

Depending on the customer specification, the addition rate may need to be increased to 3% or 4% to allow for the correct amount of additives or pigment to be present within the final component.

There are several other benefits to using a higher addition rate masterbatch:

Reputable Masterbatch suppliers will always consider the customers best option and work closely with their customers to develop a custom solution that meets their specific needs, taking into account factors such as processing conditions, end-use application, and regulatory requirements. They should also provide guidance on optimal addition rates to ensure the desired colour properties are achieved while minimizing any negative impact on the physical and mechanical properties of the end product.